Apple announced today that it will speed up its efforts to use more recovered materials in its products. This includes a new goal of using recycled cobalt in all Apple-designed batteries by 2025.

Also, by 2025, all of the rare earth elements used in Apple devices’ magnets will be recycled. All of Apple’s printed circuit boards will be made with 100 percent recycled tin soldering and 100 percent recycled gold plating.

In 2022, the company made a big change in how it used key recovered metals. It now gets more than two-thirds of its aluminum, almost three-quarters of its rare earth, and more than 95 percent of its tungsten from 100% recycled materials.

This fast progress moves Apple closer to its goal of making all of its products out of recycled and green materials one day. It also helps the company move toward its goal of making all of its products carbon-neutral by 2030.

Tim Cook, the CEO of Apple, said, “Every day, Apple comes up with new ways to make technology that improves people’s lives and protects the planet we all live on.” “Our environmental work is part of everything we make and who we are, from the recycled materials in our goods to the clean energy that runs our business. So, we’ll keep going because we think good technology should be good for both our users and the world.

“Our goal is to use 100 percent recycled and renewable materials in our products one day,” said Lisa Jackson, Apple’s vice president of Environment, Policy, and Social Initiatives. “This goal goes hand in hand with Apple 2030, our plan to make carbon-neutral products by 2030.” “We’re working quickly toward both goals, and in the process, we’re pushing innovation forward in our whole industry.”

Charting Progress to 2025

Over the past three years, Apple has greatly increased the amount of 100% certified recovered cobalt it uses. This means that by 2025, all batteries made by Apple will use recycled cobalt. In 2022, 25% of the cobalt in Apple goods came from recycled materials, which is up from 13% the year before.

Cobalt is an important part of the batteries used in most household electronics, including Apple devices. It allows for high energy density while also meeting Apple’s strict standards for durability and safety. Most of the cobalt that Apple uses goes into making batteries for its iPhone, iPad, Apple Watch, MacBook, and many other goods.

The company’s use of 100% approved recycled rare earth elements has also grown a lot in the last year, from 45% in 2021 to 73.3% in 2022. Since using recovered rare earths for the first time in the Taptic Engine of the iPhone 11, Apple has used the material in more of its products, including all of the magnets in the newest iPhone, iPad, Apple Watch, MacBook, and Mac models.

As magnets are by far Apple’s biggest use of rare earths, the new 2025 goal means that almost all rare earths in Apple goods will soon be recycled.

By 2025, the company will use only certified recycled tin solder on all printed rigid and flexible circuit boards that were created by Apple. In recent years, Apple has started using recovered tin in the solder of many flexible printed circuit boards in its products.

Last year, 38 percent of the tin used came from recycled sources. Even more parts are being made with recycled tin, and the company is getting more sources involved in this effort.

Apple has also made movement toward another of its 2025 goals, which is to stop using plastics in its packaging. Apple has stayed on track toward this lofty goal by coming up with fiber alternatives for things like screen films, wraps, and foam cushioning.

Apple is coming up with new ways to replace labels, lamination, and other small uses of plastic to get rid of the last 4 percent of plastic used in the company’s packing. Apple made a custom printer in the past year so that digital writing could be done directly on the boxes of the iPhone 14 and iPhone 14 Pro.

This made most labels unnecessary. And the polypropylene plastic lamination on boxes and packaging parts has been replaced with a new overprint varnish found on the packing for the iPad Air, iPad Pro, and Apple Watch Series 8. Over 1,100 metric tons of plastic and over 2,400 metric tons of carbon dioxide were saved because of the new idea.

Progress in Responsible Sourcing of Primary and Recycled Materials

As Apple uses fewer recently mined minerals, it is also looking for ways to help the people whose lives depend on mining. The company is working with experts like the Fund for Global Human Rights to support people who fight for human rights and the environment on the front lines.

This includes people in the African Great Lakes region. The company is also working on vocational education programs to help people in the area who want to leave mining get new skills and find new opportunities.

Apple gets its main minerals in a responsible way and makes sure that all of its suppliers follow the highest standards for human rights and the environment. Apple was the first electronics company to post a list of cobalt refiners in 2016 and a list of lithium refiners in 2020.

These refiners are part of Apple’s battery supply chain. In 2017, the company made a picture of its rare earths supply chain. And since 2015, every known tin, tungsten, tantalum, and gold smelter and refiner has taken part in exams by a third party.

Apple has given priority to 14 materials based on their impact on the environment, human rights, and the supply chain.

Together, these 14 materials make up nearly 90% of the material shipped in Apple products. They are aluminum, cobalt, copper, glass, gold, lithium, paper, plastics, rare earth elements, steel, tantalum, tin, tungsten, and zinc.

About 20% of the materials used to make Apple goods that were shipped in 2022 came from recycled or renewable sources.

This includes the first use of recycled copper foil in the main logic board of the 10th-generation iPad, the use of certified recycled steel in the battery tray of the MacBook Air with the M2 chip, the use of 100% recycled tungsten in the latest line of Apple Watches, and the use of an Apple-designed aluminum alloy to make the enclosures of many Apple products.

Innovating for the Future of Recycling

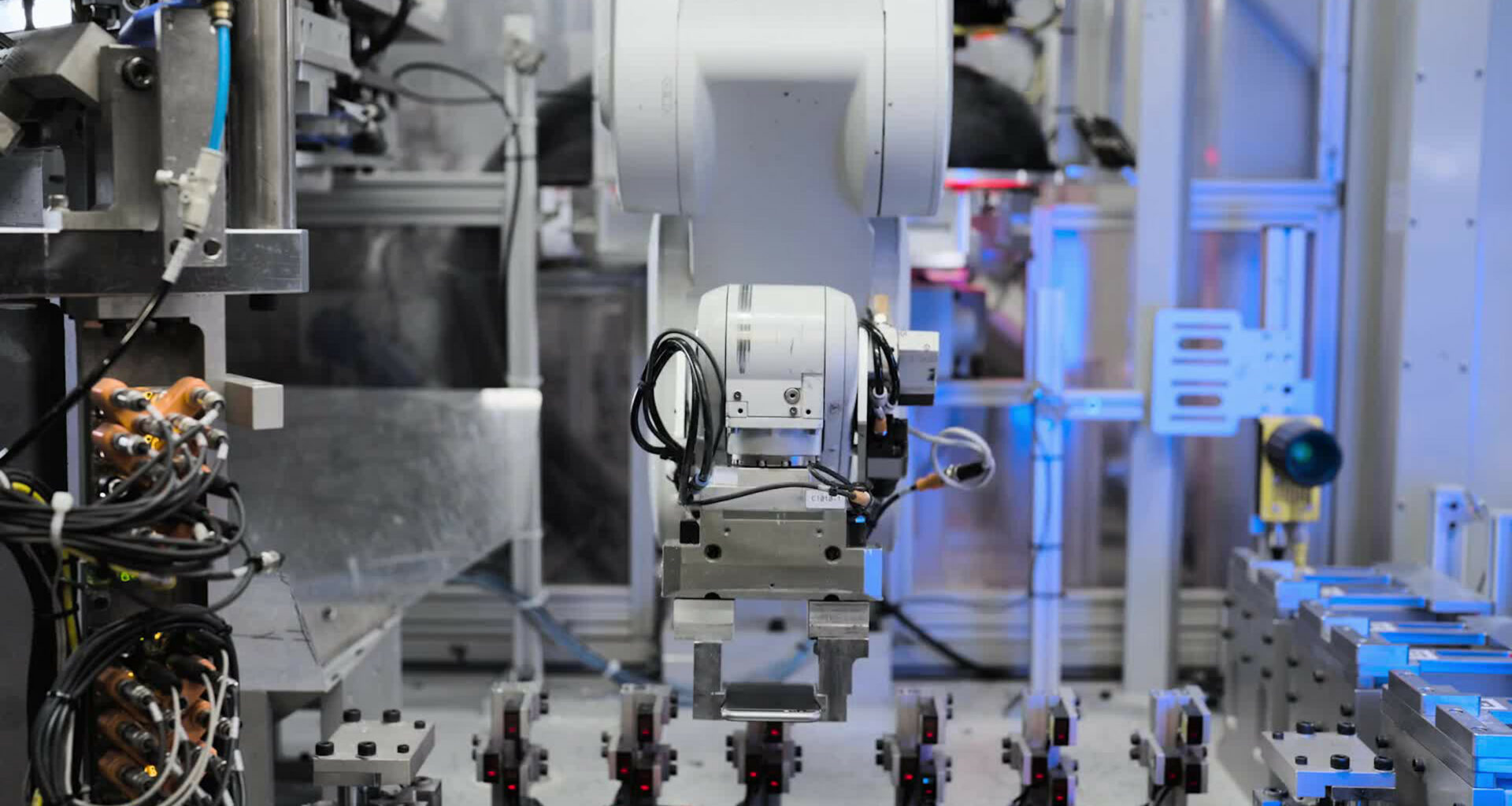

Apple’s work to be a leader in new research and development for disassembling and recycling electronics at the end of their lives has helped this growth happen.

Through a lot of work, including partnerships with top research institutions and the Material Recovery Lab in Austin, Texas, Apple engineers and experts are coming up with new ways to reuse the materials in Apple products. They are also helping design decisions that make it easier to take apart and recover the materials.

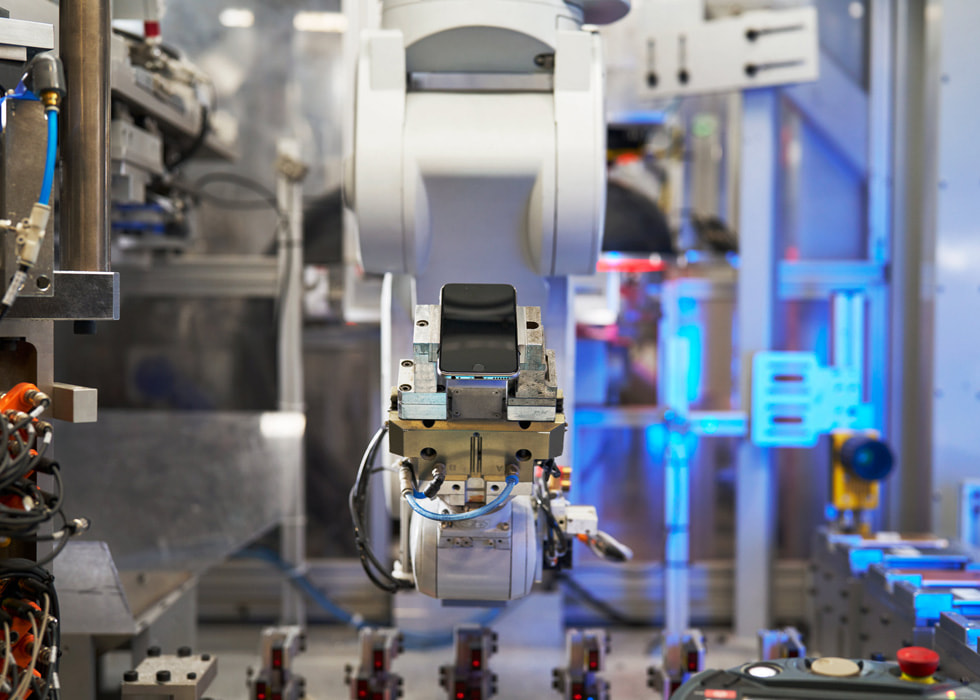

Daisy, the company’s robot for taking apart iPhones, sorts the batteries from the other parts. This lets specialty recyclers get back cobalt and other materials, like lithium. Apple thinks that more than 11,000 kilograms of cobalt have been reclaimed from Daisy batteries and sold on the secondary market since 2019. Daisy also helps get back rare earth elements that are usually lost when gadgets are recycled the old way.

Daisy is just one example of how Apple’s new ideas about reusing and taking things apart can change the whole industry. By taking apart Taptic Engines, the company’s Dave robot, which is now being used by a recycling partner in China, can help speed up the collection of rare earth elements even more.

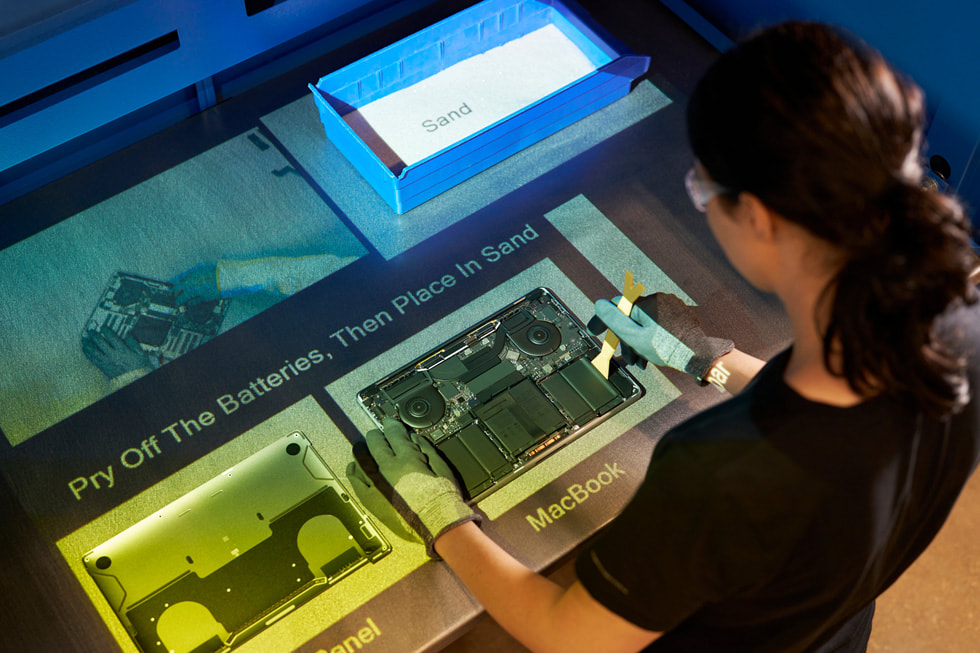

Apple has also started to give its recycling partners virtual reality (AR) systems that use overhead projectors. By projecting video images right onto a work area, the system shows how to take apart devices like the MacBook and iPad.

The company puts out Apple Recycler Guides to help recyclers all over the world get the most out of recovering materials while keeping people’s health and safety in mind. As recycled and renewable materials can help lower a product’s carbon footprint, Apple is getting closer to its lofty goal of making its entire supply chain and the life cycle of every product carbon neutral by 2030.

Read More:

AMD Ryzen 9 7950X is a Great Deal at 27% Off, and There Are Other Great Deals on CPUs as Well.

A Fake Ernie Bot App Is Being Sued by Baidu by Apple and App Developers

A Fake Ernie Bot App Is Being Sued by Baidu by Apple and App Developers